2205 Duplex Stainless Steel Plate

2205 Duplex stainless steel alloy is a duplex stainless steel composed of 22% chromium, 2.5% molybdenum and 4.5% nickel nitrogen alloy. It has high strength, good impact toughness and good overall and local resistance to stress corrosion.

2205 Duplex Stainless Steel Plate Description

The yield strength of 2205 Duplex stainless steel is more than twice that of ordinary austenitic stainless steel, and it has enough plastic toughness required for molding. The wall thickness of storage tanks or pressure vessels made of duplex stainless steel is 30-50% less than that of commonly used austenite, which is conducive to reducing costs. Moreover, it has good local corrosion resistance, and compared with austenitic stainless steel with similar alloy content, its wear corrosion resistance and fatigue corrosion performance are better than austenitic stainless steel. Whether under dynamic load or static load conditions, 2205 duplex stainless steel has a higher energy absorption capacity than austenitic stainless steel, which has obvious advantages for structural parts to cope with emergencies such as collisions, explosions, etc..

Product Parameters

| STAINLESS STEEL PLATE | |

|---|---|

| Product Name | Stainless Steel Plate, Stainless Stainless Sheet |

| Standard | GB, AISI, ASTM,DIN, EN, JIS |

| Available Grades | 200 Series: 201, 202 |

| 300 Series: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H | |

| 400 Series: 409, 410S, 416, 420, 430, 439, 440, 444, 446 | |

| Duplex and Others: 2205, 2507, S31803, S32205, S32750, S32760, 253MA, 254SMO, 904L etc | |

| Process | Hot Rolled, Cold Rolled, Forged |

| Sizes | Thickness: 0.3-200mm, Width: 10-4000mm (according to customer's request) |

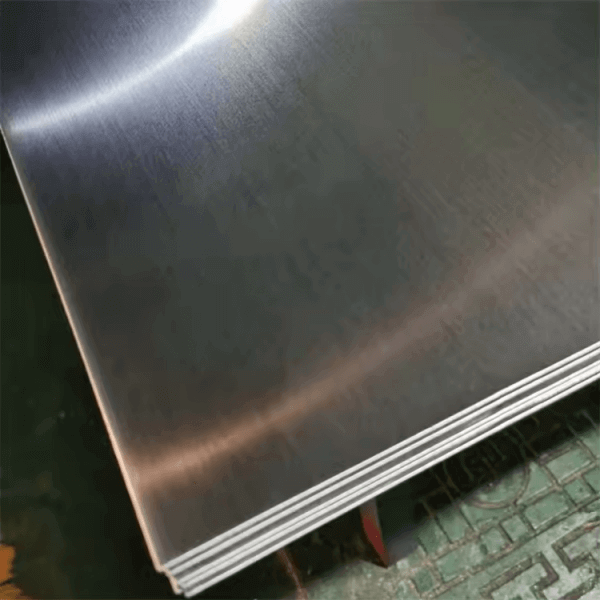

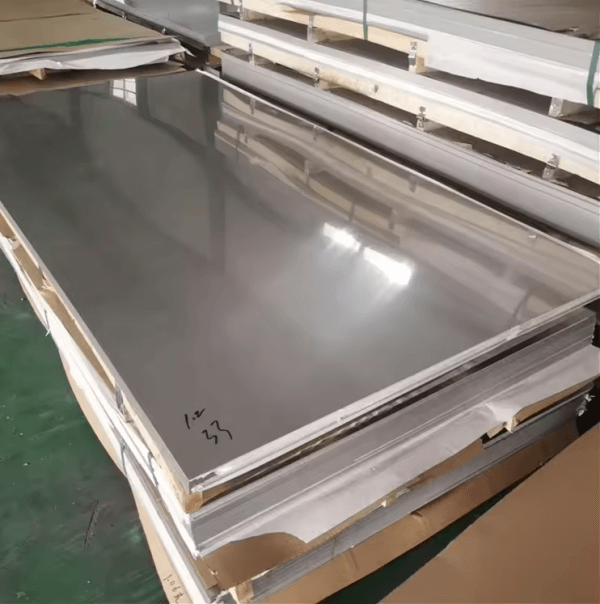

| Surface Treatment | NO.1, 1D, 2D, 2B, NO.4, BA, HL, Mirror, Embossim, Sandblasted |

| Fabricating | Rolling, Bending, Sllitting, Decoiling, Cutting, Drilling, Punching, Beveling, Welding etc. |

| Application | Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

| FINISH | DESCRIPTION | THICKNESS (MM) | WIDTH (MM) |

|---|---|---|---|

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.7 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.9 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.2 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.5 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.6 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.5 | 914, 1219 & 1500 |

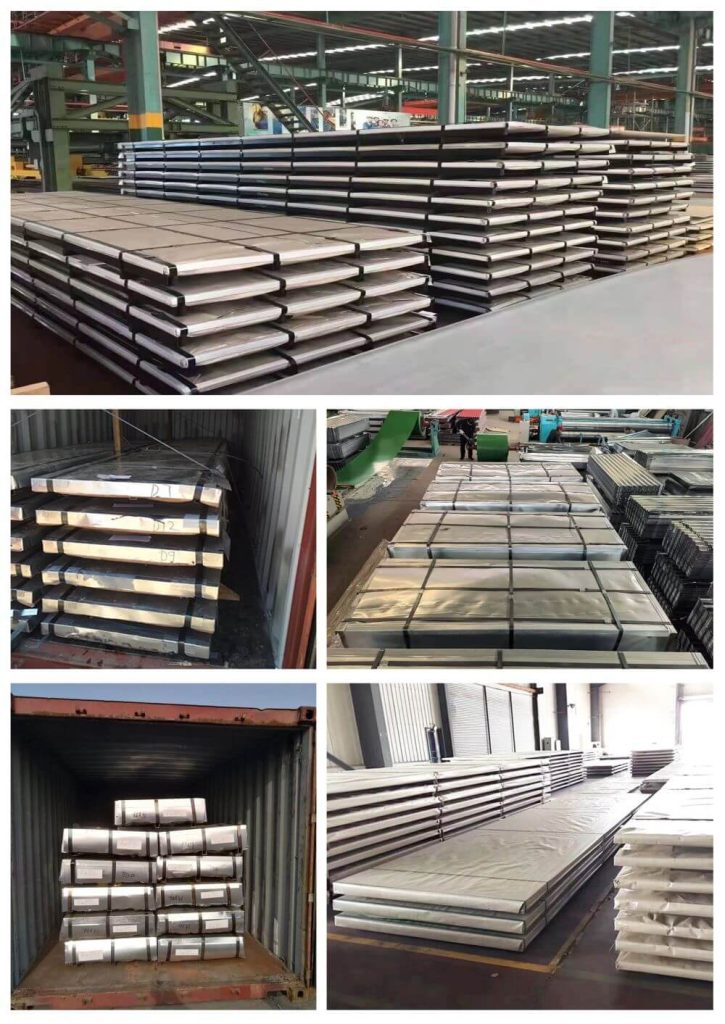

Product Package

Collect Your Quote for Right Now

What do you need? You can leave your requirements here.