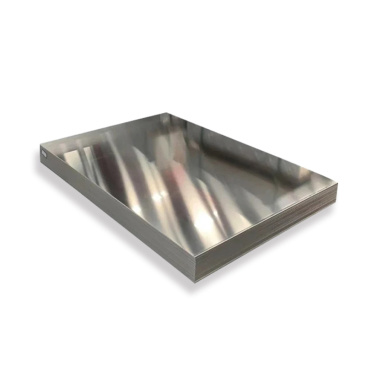

2507 Duplex Stainless Steel Plate

2507 duplex stainless steel is a special ferritic-austenitic duplex stainless steel with excellent corrosion resistance. It achieves comprehensive protection against point corrosion, crevice corrosion and uniform corrosion through the ratio of chromium and molybdenum elements.

2507 Duplex Stainless Steel Plate Description

2507 is an ultra-duplex stainless steel containing 25% chromium, 4% molybdenum and 7% nickel. In terms of chemical composition, the chromium and molybdenum content of 2507 stainless steel is relatively high, which leads to its super-strong corrosion resistance to various acids. The duplex construction of 2507 stainless steel gives it excellent resistance in the face of stress corrosion cracking. Cracks are an inevitable problem in construction and other related fields, and 2507 stainless steel exhibits excellent corrosion resistance in an environment containing chloride ions, which makes it ideal for construction and related industries. In addition to its excellent corrosion resistance, 2507 stainless steel also has excellent mechanical properties. It has high compressive strength, impact strength and low coefficient of thermal expansion, which makes it widely used in oil and gas industry, water treatment, fire protection, desalination equipment, mechanical parts and fuel gas purification equipment

Product Parameters

| STAINLESS STEEL PLATE | |

|---|---|

| Product Name | Stainless Steel Plate, Stainless Stainless Sheet |

| Standard | GB, AISI, ASTM,DIN, EN, JIS |

| Available Grades | 200 Series: 201, 202 |

| 300 Series: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H | |

| 400 Series: 409, 410S, 416, 420, 430, 439, 440, 444, 446 | |

| Duplex and Others: 2205, 2507, S31803, S32205, S32750, S32760, 253MA, 254SMO, 904L etc | |

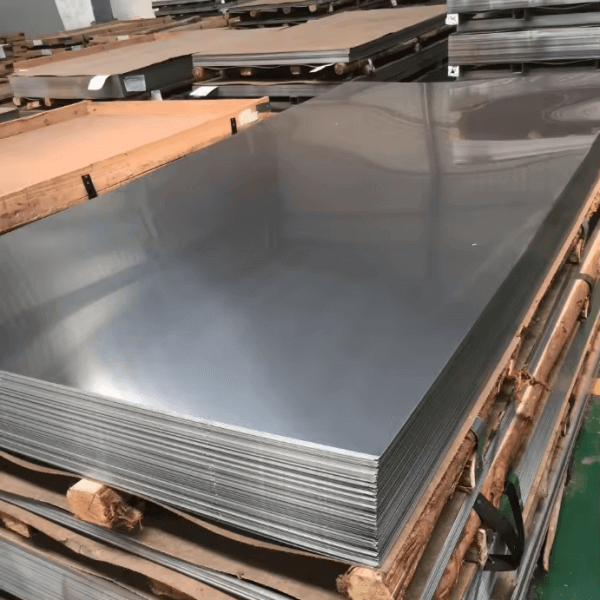

| Process | Hot Rolled, Cold Rolled, Forged |

| Sizes | Thickness: 0.3-200mm, Width: 10-4000mm (according to customer's request) |

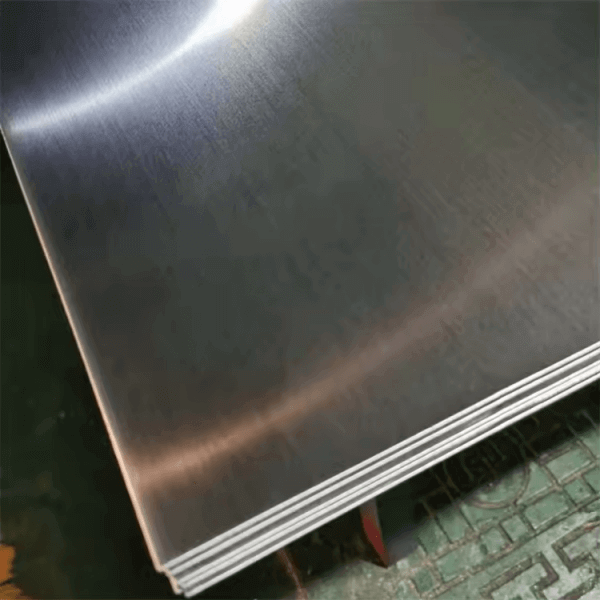

| Surface Treatment | NO.1, 1D, 2D, 2B, NO.4, BA, HL, Mirror, Embossim, Sandblasted |

| Fabricating | Rolling, Bending, Sllitting, Decoiling, Cutting, Drilling, Punching, Beveling, Welding etc. |

| Application | Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

| FINISH | DESCRIPTION | THICKNESS (MM) | WIDTH (MM) |

|---|---|---|---|

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.7 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.9 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.2 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.5 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.6 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.5 | 914, 1219 & 1500 |

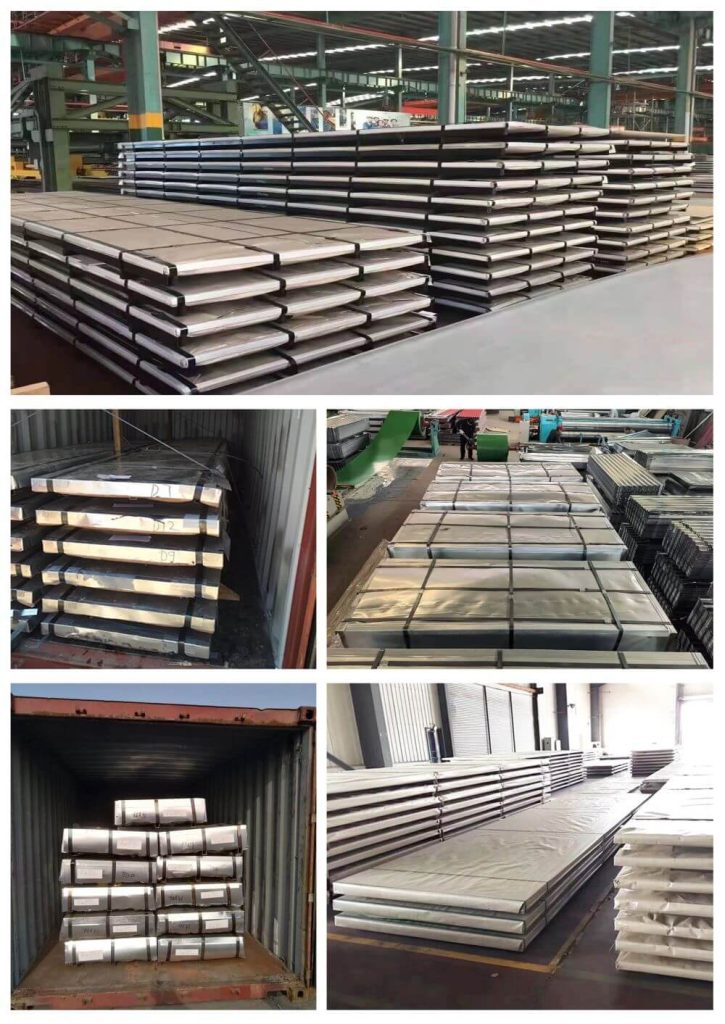

Product Package

Collect Your Quote for Right Now

What do you need? You can leave your requirements here.