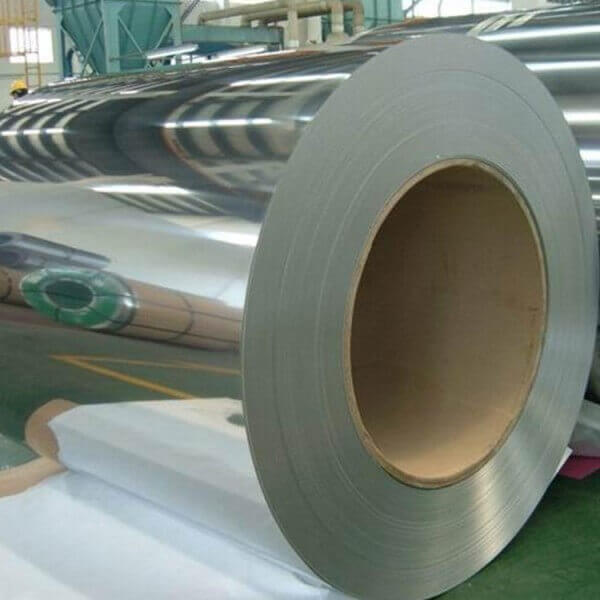

304L Stainless Steel Coil

304L stainless steel is remarkably similar to 304 stainless steel in their chemical composition with one key difference. the maximum carbon of 304L stainless steel content is set at 0.08%, whereas grade 304L stainless steel has a maximum carbon content of 0.03%. This is why the “L” in 304L can be interpreted as extra-low carbon. It is widely used in the production of equipment and parts that demand better corrosion resistance and formability.

304L Stainless Steel Coil Description

304L stainless steel coil is a variant of 304 stainless steel coil with a lower carbon content and is used where welding is involved. The lower carbon content minimizes the precipitation of carbides in the heat-affected zone close to the weld, and the precipitation of carbides may lead to intergranular corrosion of stainless steel in certain settings. Basically, using 304L spares the need to anneal weld joints prior to using the completed metal form, saving time and effort. Generally speaking, both 304 and 304L stainless steel coils can be used for many of the same applications. The differences are often minor enough that one isn’t considered massively more useful over the other. 304L stainless steel coil is widely used in fields such as food processing equipment, building materials, automobile parts.

Product Parameters

| PRODUCT NAME | STAINLESS STEEL COIL |

|---|---|

| Type | Steel Coil |

| Thickness | 2.5mm-10.0mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610mm-2000mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, |

| Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. | |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

| FINISH | DESCRIPTION | THICKNESS (MM) | WIDTH (MM) |

|---|---|---|---|

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.7 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.9 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.2 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.5 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.6 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.5 | 914, 1219 & 1500 |

Product Package

Collect Your Quote for Right Now

What do you need? You can leave your requirements here.