316L Stainless Steel Plate

316L stainless steel has a lower proportion of carbon in its composition. To qualify as 316L stainless steel, the amount of carbon cannot exceed 0.03%. This decreases the risk of carbon precipitation, making it a better option for welding to ensure maximum corrosion resistance.

316L Stainless Steel Plate Description

316L stainless steel is a variant of 316 stainless steel with a lower carbon content and is used where welding is required. The lower carbon content minimizes the precipitation of carbides in the heat-affected zone close to the weld, and the precipitation of carbides may cause intergranular corrosion of stainless steel in certain environments. Basically, using 316L eliminates the need to anneal weld joints prior to using the completed metal form, saving time and effort. 316L stainless steel is the second most widely used stainless steel after 304, and its corrosion resistance is better than 304. High temperature resistance is also better, up to 1000 degrees. 316L stainless steel is a kind of universal stainless steel material, rust resistance is stronger than 200 series stainless steel material. 316L stainless steel is widely used in the chemical industry because of its excellent corrosion resistance.

Product Parameters

| STAINLESS STEEL PLATE | |

|---|---|

| Product Name | Stainless Steel Plate, Stainless Stainless Sheet |

| Standard | GB, AISI, ASTM,DIN, EN, JIS |

| Available Grades | 200 Series: 201, 202 |

| 300 Series: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H | |

| 400 Series: 409, 410S, 416, 420, 430, 439, 440, 444, 446 | |

| Duplex and Others: 2205, 2507, S31803, S32205, S32750, S32760, 253MA, 254SMO, 904L etc | |

| Process | Hot Rolled, Cold Rolled, Forged |

| Sizes | Thickness: 0.3-200mm, Width: 10-4000mm (according to customer's request) |

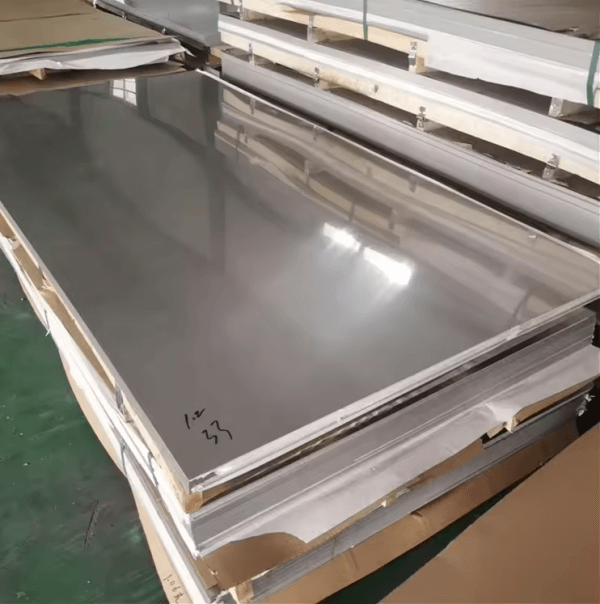

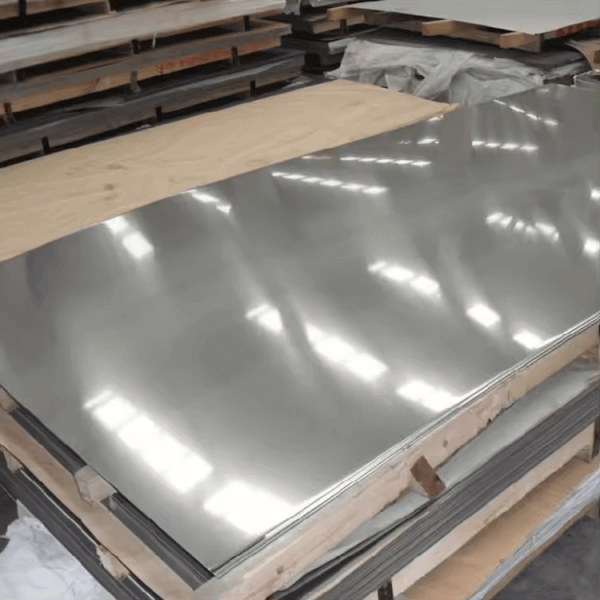

| Surface Treatment | NO.1, 1D, 2D, 2B, NO.4, BA, HL, Mirror, Embossim, Sandblasted |

| Fabricating | Rolling, Bending, Sllitting, Decoiling, Cutting, Drilling, Punching, Beveling, Welding etc. |

| Application | Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

| FINISH | DESCRIPTION | THICKNESS (MM) | WIDTH (MM) |

|---|---|---|---|

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.7 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.9 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.2 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.5 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.6 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.5 | 914, 1219 & 1500 |

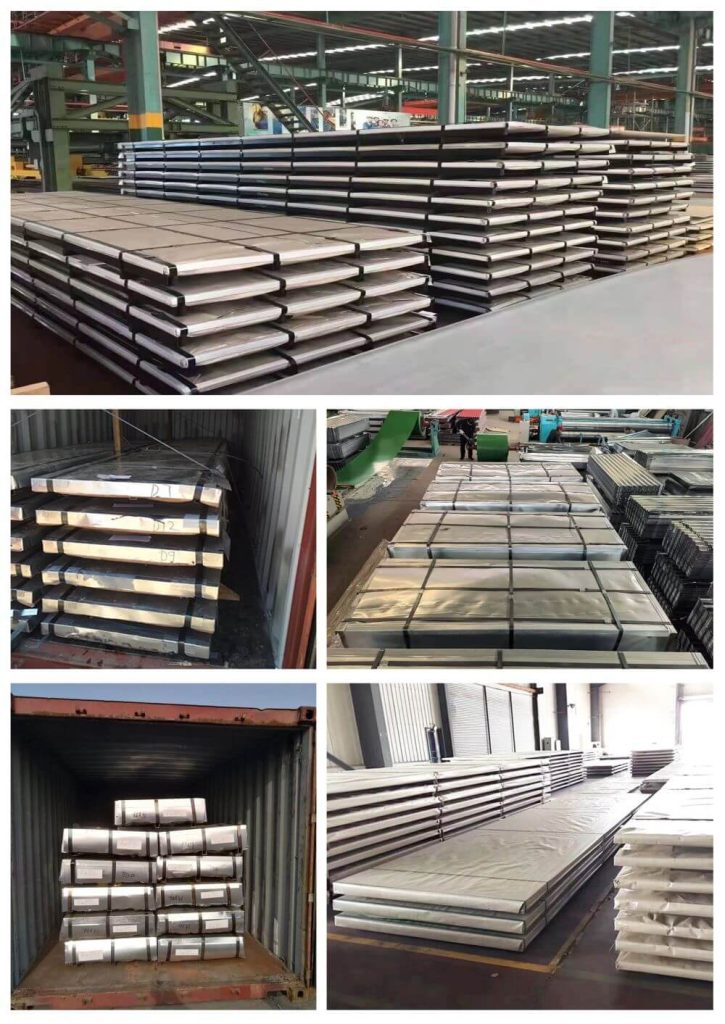

Product Package

Collect Your Quote for Right Now

What do you need? You can leave your requirements here.