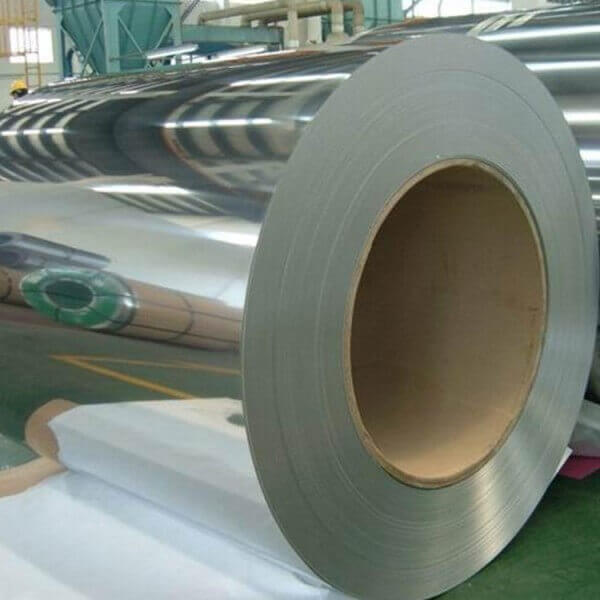

321 Stainless Steel Coil

321 stainless steel is an austenitic stainless steel of excellent corrosion resistance at room temperature, as well as good high-temperature strength and creep resistance.

321 Stainless Steel Coil Description

321 stainless steel has better crack resistance during the welding process owing to the titanium content. Besides, 321 stainless steel also has good processing and welding properties, which makes it easy to perform cutting, bending, welding and other processing operations. Its mechanical properties such as tensile strength, flexural strength and elongation are also outstanding, and can fulfill the requirements of use in various complex environments. Because 321 stainless steel coils have excellent corrosion resistance and high temperature performance, they are often used in petroleum, chemical industry, aviation, aerospace fields. In the petroleum and chemical industries, since the production process involves a large amount of corrosive media such as acids, alkalis, and salts, 321 stainless steel coil manages to resist the corrosion of these media and ensure the long-term stable operation of the equipment.

Product Parameters

| PRODUCT NAME | STAINLESS STEEL COIL |

|---|---|

| Type | Steel Coil |

| Thickness | 2.5mm-10.0mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610mm-2000mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, |

| Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. | |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

| FINISH | DESCRIPTION | THICKNESS (MM) | WIDTH (MM) |

|---|---|---|---|

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.7 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.9 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.2 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.5 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.6 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.5 | 914, 1219 & 1500 |

Product Package

Collect Your Quote for Right Now

What do you need? You can leave your requirements here.