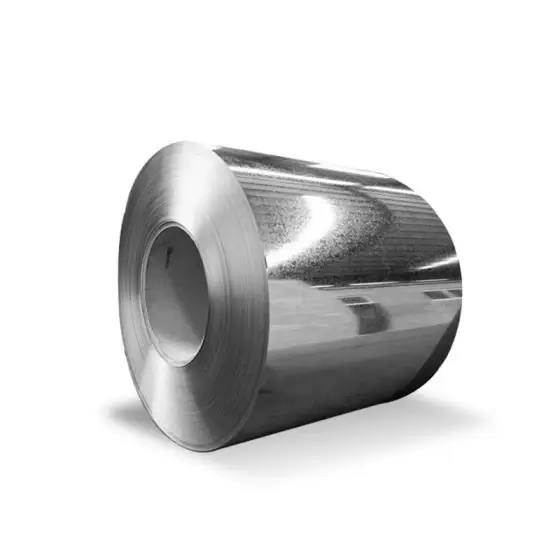

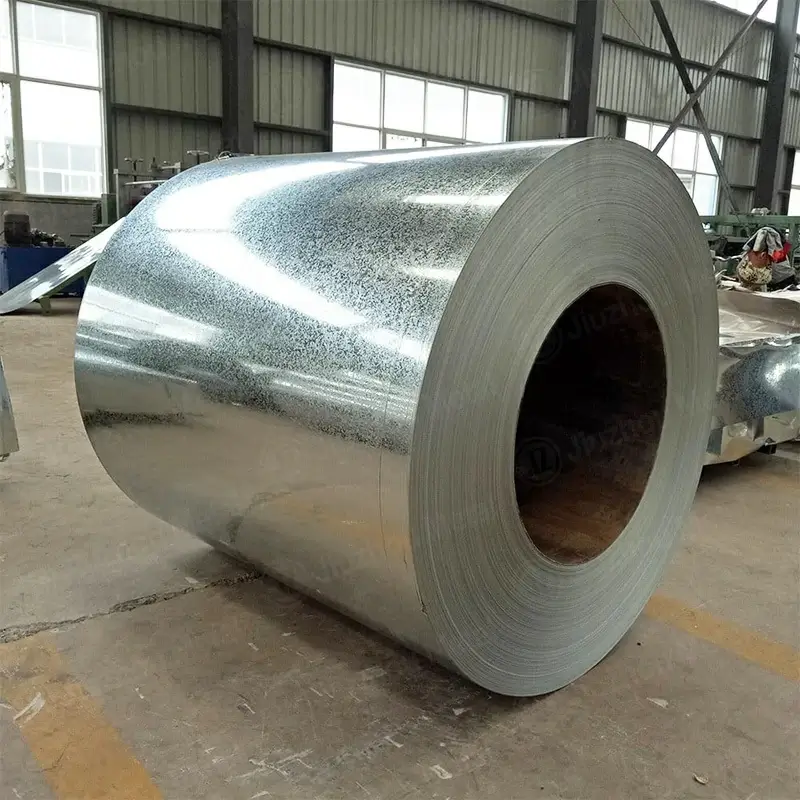

Galvanized Coil

Galvanized coil is made of a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So it is also known as cold galvanized steel.

Galvanized Coil Description

Through electrolytic galvanizing, a uniform and dense zinc layer is finally formed on the surface of the steel, but the mechanical properties of the material are still maintained. Electrogalvanized steel is usually sold in coil or sheet form. EG coil is a kind of material that can be cut, slitted and profiled for other purposes. The steel grade of galvanized steel consists of base metal grade, galvanized (E), galvanized layer type and weight. The electro-galvanized products based on SPCC, SPCD, SPCE, SPCF and SPCG are named SECC, SECD, SECE, SECF and SECG respectively.

The production process of hot galvanizing is as follows:

Mother material → degreasing → water washing → pickling → water washing → rinsing → flux solution → drying → hot galvanizing → cooling → inspection → packaging

Scope of Application

For a long time, hot-dip galvanizing process has been favored by people because of its low plating cost, excellent protection characteristics and beautiful appearance. It is widely used in automobile, construction, household appliances, chemical industry, machinery, petroleum, metallurgy, light industry, transportation, electric power, aviation and marine engineering and other fields.

Product Parameters

| Product Name | Hot Dip Galvanized Coil |

|---|---|

| Thickness | 0.12mm-3.5mm |

| Width | 600mm-1500mm |

| Length | 508mm/610mm, Support Customization |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Zinc Layer | Hot Galvanizing: 60-275g/m虏 |

| Pre-galvanized: 80-275g/m虏 |

Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Ti |

|---|---|---|---|---|---|---|---|

| Forcold Forming | DX51D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 |

| Chinese Standard | DX52D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 |

| DX53D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | |

| DX54D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | |

| DX56D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | |

| DX57D+Z | 0.12 | 0.5 | 0.6 | 0.1 | 0.045 | 0.3 | |

| Forcold Forming | SGCC | 0.15 | 0.5 | 0.8 | 0.05 | 0.03 | 0.025 |

| Japanese Standard | SGCD1 | 0.12 | 0.5 | 0.6 | 0.04 | 0.03 | 0.025 |

| SGCD2 | 0.1 | 0.5 | 0.45 | 0.03 | 0.03 | 0.025 | |

| SGCD3 | 0.08 | 0.5 | 0.45 | 0.03 | 0.03 | 0.025 | |

| SGCD4 | 0.06 | 0.5 | 0.45 | 0.03 | 0.03 | 0.025 | |

| For Structure | SGC340 | 0.25 | 0.5 | 1.7 | 0.2 | 0.035 | 0.025 |

| Japanese Standard | SGC400 | 0.25 | 0.5 | 1.7 | 0.2 | 0.035 | 0.15 |

| SGC440 | 0.25 | 0.5 | 2 | 0.2 | 0.035 | 0.15 | |

| SGC490 | 0.3 | 0.5 | 2 | 0.2 | 0.035 | 0.025 | |

| SGC510 | 0.3 | 0.5 | 2.5 | 0.2 | 0.035 | 0.025 | |

| For Structure | S220GD+Z | 0.2 | 0.6 | 0.7 | 0.1 | 0.045 | 0.025 |

| AISI Standard | S250GD+Z | 0.2 | 0.6 | 0.7 | 0.1 | 0.045 | 0.025 |

| S280GD+Z | 0.2 | 0.6 | 0.7 | 0.1 | 0.045 | 0.025 | |

| S320GD+Z | 0.2 | 0.6 | 0.7 | 0.1 | 0.045 | 0.025 | |

| S350GD+Z | 0.2 | 0.6 | 0.7 | 0.1 | 0.045 | 0.15 | |

| S550GD+Z | 0.2 | 0.6 | 0.7 | 0.1 | 0.045 | 0.15 |

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

|---|---|---|---|

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | - |

Galvanized Surface Selection

| Zero Spangle | Minimized Spangle | Normal Spangle | Large Spangle |

|---|---|---|---|

|  |  |  |

| Use of The Environment | Recommended Zinc Thickness | ||

| Indoor Use | Z10 or Z12 (100g/㎡or 120g/㎡) | ||

| Suburbs | Z20 and Painting (200g/㎡) | ||

| Urban or Industrial Area | Z27 (270g/㎡) or G90 (US Standard) and painted | ||

| Coastal Area | Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted | ||

| Punch or Deep Drawing Application | Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping | ||

| Surface Treatment Type | Code | Features |

|---|---|---|

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

| Chinese Standard | Japan Standard | European Standard |

|---|---|---|

| DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

| DX52D Z/DC52D Z | SGCD1 | DX52D With |

| DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

| S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

| DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |

Scope of Application

| Aluminum Uses And Application Area | |

|---|---|

| Food Packaging | Beverage can ends, cans, bottle caps, etc. |

| Building | Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

| Transportation | Auto parts, passenger car bodies, aviation ships and air cargo containers. |

| Electronic聽Equipment | Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

| Consumer Goods | Umbrellas, cooking utensils, sports equipment, etc |

| Other | Military, color coated aluminum plate |

Product Package

What do you need? You can leave your requirements here.